Hardness Tester Features:

This digital Rockwell hardness tester with fully automated load/unload procedures affords highly sensitive and accurate readings. Micro computer controlled with USB output to built-in mini printer or PC. Utilizing the guidelines of ASTM E-18, the 900-366 digital Rockwell hardness tester offers programmable scale conversions, dwell times, statistical capabilities and test counter. Capable of testing in all of the regular Rockwell® scales.

For full conformance to the latest E18-20 specification, please call (201)962-7373

Automatic conversions to: HRN, HRT, HB, HV, HLD and σb.

Specifications:

| Minor Load | 10 Kgf |

|---|---|

| Major Load | 60 Kgf, 100 Kgf, 150 KGF |

| Test Force Application | Dead Weight |

| Test Force Control | Motorized |

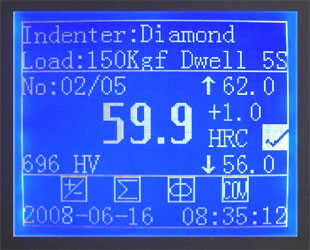

| Results Display | Hi Def LCD Digital Readout |

| Resolution | 0.1HR |

| Vertical Capacity | 16.5″ |

| Memory/Output | 500 Tests/USB |

| Throat Depth | 6.50″ |

| Height | 28.34″ |

| Width | 7.87″ |

| Depth | 21.60″ |

Standard Accessories:

- C-scale Diamond Indenter

- 1/16″ Ball Indenter

- Built-in Mini Printer

- Test Table 5.87″ (150mm)

- Flat Anvil 2.5″ (63mm)

- Std. Vee Anvil

- Accessory Case

- Dust Cover

- 3 piece-HRC test blocks

- 1 piece-HRB test block

Options:

- NIST/ASTM certified hardness test blocks, penetrators and kits are available.

- This model is available with ASTM E18-20 certification

The 900-366 digital Rockwell hardness tester comes complete with everything needed to test in the following

Rockwell Scales: A, B, C, D, F, G. Other Rockwell Scales can be achieved with optional indentors!

Key performance parameters

- Preload: 98.1N(10kgf)

- Total test force: 588.4N(60kgf),980.7N(100kgf),1471N(150kgf),

- Scales: HRB,HRC,HRD,HRE,HRF,HRG,HRH,HRK,HRL,HRM,HRP,HRR,HRS,HRV

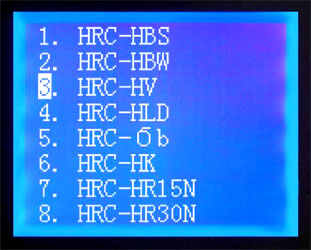

- Conversions:The 900-366 digital Rockwell hardness tester can convert the measured Rockwell hardness value to other scales or even tensile strength. Example: the value of HRA scale can be automatically converted into HBS, HBW, HV and HK value; Convert the value of HRB scale into HB10, HB30, HV, HLD, σb and HK value; Convert the value of HRC scale into HBS, HBW, HV, HLD, HR15N, HR30N, σb and HK value; Convert the value of HRD scale into HV, HK, HB value; Convert the value of HRE scale into HV, HK, HB value; Convert the value of HRF scale into HV, HB value.

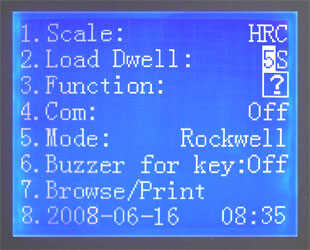

- Load cycle 3~8s

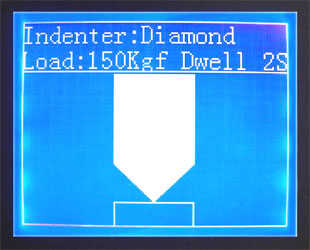

- Load dwell duration: 2~50s

- Resolution :0.1HR

- Display High definition backlight LCD

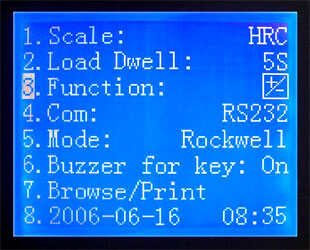

- Operation: Menu selectable, Membrane keypad

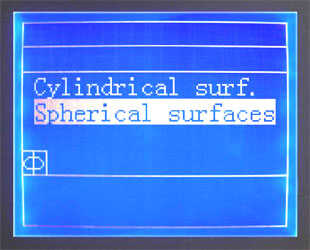

- Auxiliary functions Upper/lower limits setting& alarming, Data statistics, Avg., Max., Min., S, R, Scale conversion, HV, HB, σb, etc. Curved surface Auto Correction

- Data output: Print out, or output to PC through USB port

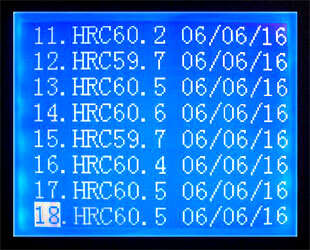

- Memory: Max 500 items of test results stored automatically

- Testing Capacity:Vertical:strong>7.87” Throat Depth:6.50”

- Dimensions::Height: 21.65” Width:10” Depth: 36.6”

- Power supply:single phase, AC, 110V, 50~60Hz, 4A

- Net weight:220 lbs (100kg)

- Shipping Weight:approx. 300 lbs

Prior to ship, please advise power setting needed.

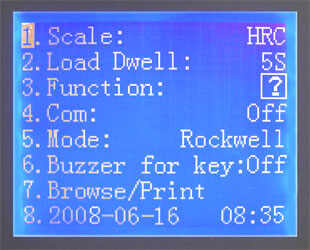

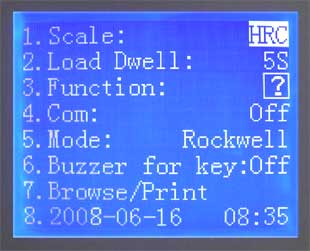

Test parameter setting

Load dwell setting

Limit setting

Data statistics

Scale conversion

Browse through/print from memory

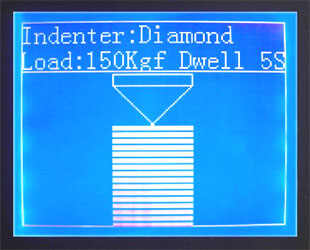

Testing: Preload

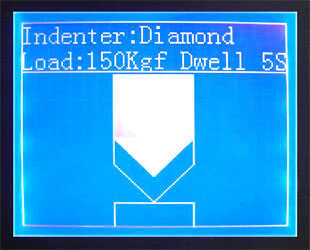

Automatic testing

Rockwell Hardness Tester Scale/Indentor/Load chart

| Scale Symbol | Indenter Type Ball dimensions indicate diameter |

Preliminary Force N (kgf)> | Total Force N (kgf) | Typical Application |

|---|---|---|---|---|

| A | Spheroconical Diamond | 98.07 (10) | 588.4 (60) | Cemented carbides, thin steel and shallow case hardened steel |

| B | Ball 1/16″ (1.588mm) | 98.07 (10) | 980.7 (100) | Copper alloys, soft steels, alum. Alloys, malleable iron, etc. |

| C | Spheroconical Diamond | 98.07 (10) | 1471 (150) | Steel, hard cast irons,pearltic malleable iron, titanium, deep case hardened steel & other material harder than HRB 100 |

| D | Spheroconical Diamond | 98.07 (10) | 980.7 (100) | Thin steel and medium case hardened steel and pearlitic malleable iron |

| E | Ball – 1/8″ (3.175mm) | 98.07 (10) | 980.7 (100) | Cast iron, aluminum&magnesium alloys and bearing metals |

| F | Ball – 1/16″ (1.588mm) | 98.07 (10) | 588.4 (60) | Annealed copper alloys, and thin soft sheet metals |

| G | Ball – 1/16″ (1.588mm) | 98.07 (10) | 1471 (150) | Malleable irons, copper-nckel-zinc and cupronickel alloys |

| H | Ball – 1/8″ (3.175mm) | 98.07 (10) | 588.4 (60) | Aluminum, zinc and lead |

| K | Ball – 1/8″ (3.175mm) | 98.07 (10) | 1471 (150) | Bearing metals and other very soft or thin materials. Use smallest ball and heaviest load that does not give anvil effect |

| L | Ball – 1/4″ (6.350mm) | 98.07 (10) | 588.4 (60) | |

| M | Ball – 1/4″ (6.350mm) | 98.07 (10) | 980.7 (100) | |

| P | Ball – 1/4″ (6.350mm) | 98.07 (10) | 1471 (150) | |

| R | Ball – 1/2″ (12.70mm) | 98.07 (10) | 588.4 (60) | |

| S | Ball – 1/2″ (12.70mm) | 98.07 (10) | 980.7 (100) | |

| V | Ball – 1/2″ (12.70mm) | 98.07 (10) | 1471 (150) |

HARNDESS TESTING RESOURCES:

- REBUILT INVENTORY W/ FULL WARRANTY

- PHASE II WARRANTY CARD

- PHASE II SAMPLE EVALUATION SHEETS

- HARDNESS TESTER CONVERSION CHART

- PRINCIPLE OF ROCKWELL HARDNESS TESTING

- ROUNDNESS CORRECTION CHART FOR HARNDESS TESTING

- PORTABLE HARDNESS TESTERS

- MINIMUM THICKNESS CHART FOR ROCKWELL HARDNESS TESTING

- ROCKWELL HARDNESS SCALE INDENTOR LOAD CHART

- NIST LINKS

- NIST SCALE HISTORY

- ASTM LINKS