SRG-4600 surface roughness tester features:

- 9 Different roughness parameters

- Inside/Outside Diameters

- Stylus position indicator

- USB/Bluetooth output to PC

- Large Memory

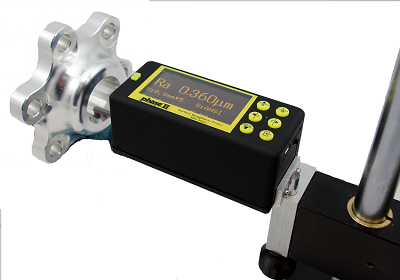

The newest addition to our state-of-the-art surface roughness testers /profilometers, the SRG-4600 will instill the highest level of confidence in your production, shop floor or QC lab. These surface roughness testers/profilometers are distinguished by a high level of accuracy, multiple parameters and simplicity of operation. Extremely sensitive and highly accurate readings from this Phase II surface roughness tester/profilometer is offered via 9 popular surface roughness scales including Ra, Rq(Rms), Rt, Rz and Rmax.

The newest addition to our state-of-the-art surface roughness testers /profilometers, the SRG-4600 will instill the highest level of confidence in your production, shop floor or QC lab.Extended memory and output coupled with many updated useful functions, the SRG-4600 surface roughness tester/profilometer is clearly the new leader in ultra accurate surface roughness/profile testing. These surface roughness testers/profilometers are distinguished by a high level of accuracy, multiple parameters and simplicity of operation. Extremely sensitive and highly accurate readings from this Phase II surface roughness tester/profilometer is offered via 9 popular surface roughness scales including Ra, Rq(Rms), Rt, Rz and Rmax.

The new diamond stylus is hypersensitive and sophisticated enough to allow for a .001 (um) micron display resolution. The SRG-4600 surface roughness tester/profilometer can utilize an easy interface to allow for changes of in/mm (uin/um), cutoff length, sampling length, parameters, level of test(stylus position), digital filters and more! Surface roughness measurement results are displayed as large characters on the LCD screen for easy recognition. Battery powered

portability allows the SRG-4600 surface roughness tester/profilometer to mobilize productivity throughout the shop.Further, a wireless Bluetooth auto-start comes standard with each unit. Optional Micro Printer is available, as well as optional stand.

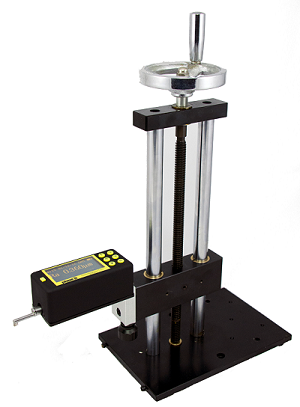

Precision Support Stand

Can be used with either 4000,4500 & 4600 series surface roughness testers

Standard 5µm Stylus

For use on flat and slightly curved surfaces

Deep Groove Stylus

For use on deep grooves with min. width of 3mm

and max depth of 10mm. Must be used with support

stand shown below

Small Hole Stylus

For use in small holes under 2mm diameter and max depth of 9mm

Curved Surface Stylus

For use on curved surface with a minimum

curvature radius of 3mm. Must be used with support

stand shown below

2″ Stylus Extension

Adds extra 2″ reach for deeper applications

5″ Stylus Extension

Adds extra 5″ reach for deeper applications

Surface roughness, for purposes of this forum, is the result of some machining process and its effect on the material surface in question.

Skid type surface roughness testers / profilometers are common instruments used on the shop floor. A diamond stylus is traversed across the specimen and a piezoelectric pickup records all vertical movement. Peaks and valleys are recorded and converted into a known value of a given parameter.

Parameters differ in how they approach looking at peaks and valleys. The most popular parameter is “Ra”. Ra is commonly defined as the arithmetic average roughness. While the Ra parameter is easy and efficient, there are other parameters that can be more specific and useful depending on the application requirements. It is the parameters that enable us to define surface roughness.

Today, for the purpose of checking Ra values, the use of portable, hand held, surface roughness testers /profilometers are not only economical, but are digital and easy to use. These surface roughness testers /profilometers are a given necessity for any shop floor that receives work with Ra surface finish requirements.