Surface Roughness Testers / Profilometers

-

Surface Roughness Testers Profilometers

Surface Roughness Testers /Profilometers/Surface Finish/Ra Surface Finish

Model No. SRG-4600

Features

The newest addition to our state-of-the-art surface roughness testers /profilometers, the SRG-4600 will instill the highest level of confidence in your production, shop floor or QC lab. These surface roughness testers/profilometers are distinguished by a high level of accuracy, multiple parameters and simplicity of operation. Extremely sensitive and highly accurate readings from this Phase II surface roughness tester/profilometer is offered via 9 popular surface roughness scales including Ra, Rq(Rms), Rt, Rz and Rmax.

Model No. SRG-4600

Features

The newest addition to our state-of-the-art surface roughness testers /profilometers, the SRG-4600 will instill the highest level of confidence in your production, shop floor or QC lab. These surface roughness testers/profilometers are distinguished by a high level of accuracy, multiple parameters and simplicity of operation. Extremely sensitive and highly accurate readings from this Phase II surface roughness tester/profilometer is offered via 9 popular surface roughness scales including Ra, Rq(Rms), Rt, Rz and Rmax.

(0 reviews)

(0 reviews) -

Surface Roughness Testers Profilometers

Mini Surface Roughness Testers / Profilometer/ Surface Roughness Gage

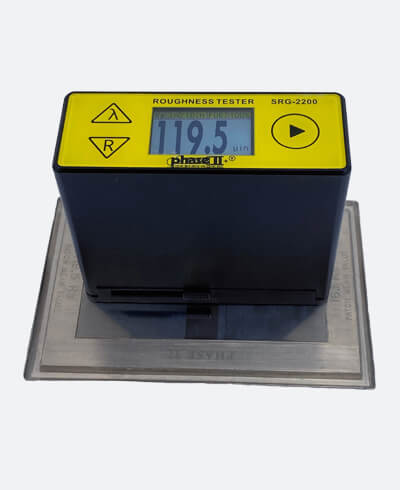

Model No. SRG-2200

Features

The New Phase II SRG-2200 Mini Surface Roughness Tester is a next generation of surface roughness tester developed by the Phase II Metrology Group that features high accuracy, a wide range of application, simple operation and stable performance. It is widely applicable in surface roughness testing all kinds of metals and non-metals.

Large memory with data output via Bluetooth.

The 1.14″ IPS TFT display shows choice of surface roughness parameter Ra, Rz, Rq and Rt at the touch of a button, combined with the selected cutoff length.

Model No. SRG-2200

Features

The New Phase II SRG-2200 Mini Surface Roughness Tester is a next generation of surface roughness tester developed by the Phase II Metrology Group that features high accuracy, a wide range of application, simple operation and stable performance. It is widely applicable in surface roughness testing all kinds of metals and non-metals.

Large memory with data output via Bluetooth.

The 1.14″ IPS TFT display shows choice of surface roughness parameter Ra, Rz, Rq and Rt at the touch of a button, combined with the selected cutoff length.

(0 reviews)

(0 reviews) -

Surface Roughness Testers Profilometers

Surface Roughness Testers /Profilometers/Surface Roughness Chart/Surface Finish Ra

Model No. SRG-4000

Features

The latest in state-of-the-art surface roughness testers profilometer, the SRG-4000 is designed with the shop environment in mind. These surface roughness testers profilometer are distinguished by a high level of accuracy, multiple parameters and simplicity of operation.

Model No. SRG-4000

Features

The latest in state-of-the-art surface roughness testers profilometer, the SRG-4000 is designed with the shop environment in mind. These surface roughness testers profilometer are distinguished by a high level of accuracy, multiple parameters and simplicity of operation.

(0 reviews)

(0 reviews) -

Surface Roughness Testers Profilometers

Surface Roughness Reference Standards/Profilometer Standards/Surface Finish Standards

Model No. SRG4600-500

Features

High quality calibration standard for portable surface roughness gauges. Ra values of 119.5 and 16.1; individually serialized and available certified to NIST.

The Phase II Reference Standard provides a reliable calibration tool which permits the technician to calibrate surface analyzing equipment to its peak efficiency.The SRG4600-500 shows the actual patch mean values of low and high microinch surfaces

Available with Lab Certification: Part No. SRG4600-505

Model No. SRG4600-500

Features

High quality calibration standard for portable surface roughness gauges. Ra values of 119.5 and 16.1; individually serialized and available certified to NIST.

The Phase II Reference Standard provides a reliable calibration tool which permits the technician to calibrate surface analyzing equipment to its peak efficiency.The SRG4600-500 shows the actual patch mean values of low and high microinch surfaces

Available with Lab Certification: Part No. SRG4600-505

(0 reviews)

(0 reviews) -

Surface Roughness Testers Profilometers

Surface Roughness Stand/Profilometer Stand

Model No. SRG-4000-050

Features

Can be used with all Phase II 4000 series surface roughness testers/profilometers.

Model No. SRG-4000-050

Features

Can be used with all Phase II 4000 series surface roughness testers/profilometers.

(0 reviews)

(0 reviews) -

Surface Roughness Testers Profilometers

Surface Roughness Tester Vise/Profilometer Vise

Model No. SRG 2000-vise

Features

The new SRG2000 VISE adds extreme versatility to your portable roughness gauge by allowing you to test small round parts effectively and accurately.

Works with the following models:

- Model No. SRG-1000

- Model No. SRG-2000

- Model No. SRG-2200

Model No. SRG 2000-vise

Features

The new SRG2000 VISE adds extreme versatility to your portable roughness gauge by allowing you to test small round parts effectively and accurately.

Works with the following models:

- Model No. SRG-1000

- Model No. SRG-2000

- Model No. SRG-2200

(0 reviews)

(0 reviews)

Surface Roughness Testers/ Profilometer Measurement Guide

Surface roughness, for purposes of this forum, is the result of some machining process and its effect on the material surface in question.

Skid type surface roughness testers / profilometers are common instruments used on the shop floor. A diamond stylus is traversed across the specimen and a piezoelectric pickup records all vertical movement. Peaks and valleys are recorded and converted into a known value of a given parameter.

Parameters differ in how they approach looking at peaks and valleys. The most popular parameter is “Ra”. Ra is commonly defined as the arithmetic average roughness. While the Ra parameter is easy and efficient, there are other parameters that can be more specific and useful depending on the application requirements. It is the parameters that enable us to define surface roughness.

Today, for the purpose of checking Ra values, the use of portable, hand held, surface roughness testers /profilometers are not only economical, but are digital and easy to use. These surface roughness testers /profilometers are a given necessity for any shop floor that receives work with Ra surface finish requirements.

SURFACE ROUGHNESS TESTERS PROFILOMETER RESOURCES:

- PHASE II WARRANTY CARD

- SURFACE ROUGHNESS MEASUREMENT GUIDE

- SURFACE ROUGHNESS PROFILE PARAMETERS

- PHASE II SAMPLE EVALUATION SHEETS

- NIST LINKS

- ASTM LINKS